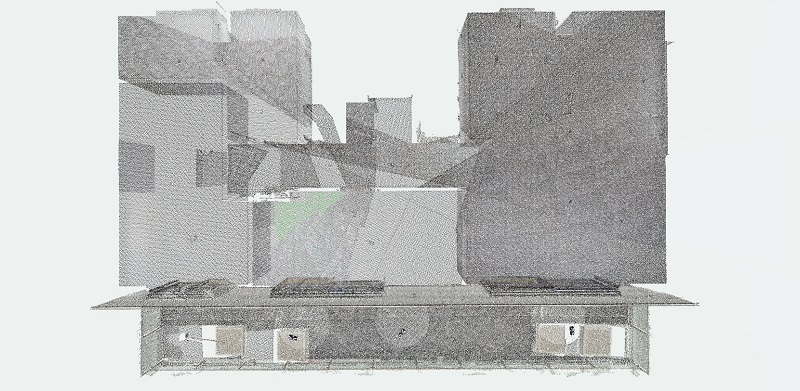

3D-Scanning

3D scanning therefore offers a multitude of advantages, ranging from the precise acquisition and reproducibility of objects to their use in virtual realities.

With the Faro© Focus System for large-scale scans and Faro© EDGE Scanarm for high-precision quality checks, we have professional and established measuring devices in the field of 3D scanning at our disposal to be able to fulfill all your customer requirements in this regard. Regardless of whether you work in mechanical engineering, plant construction, trade, health care, art and design, science and research, construction and architecture or similar, you will get a result of the highest quality from us.

3D scanning tasks:

- Creation of point clouds

- Creation of polygon models

- Creation of drawings from digitized models

- Highly accurate space recording and measurement

- Digitization of entire plant areas

- Target / actual comparison

- Quality control

- Plant measurement

- Wear tests

- Creation of digital data for 3D printing

- Building survey