Engineering / Simulation

Your competent partner for all areas of automation technology

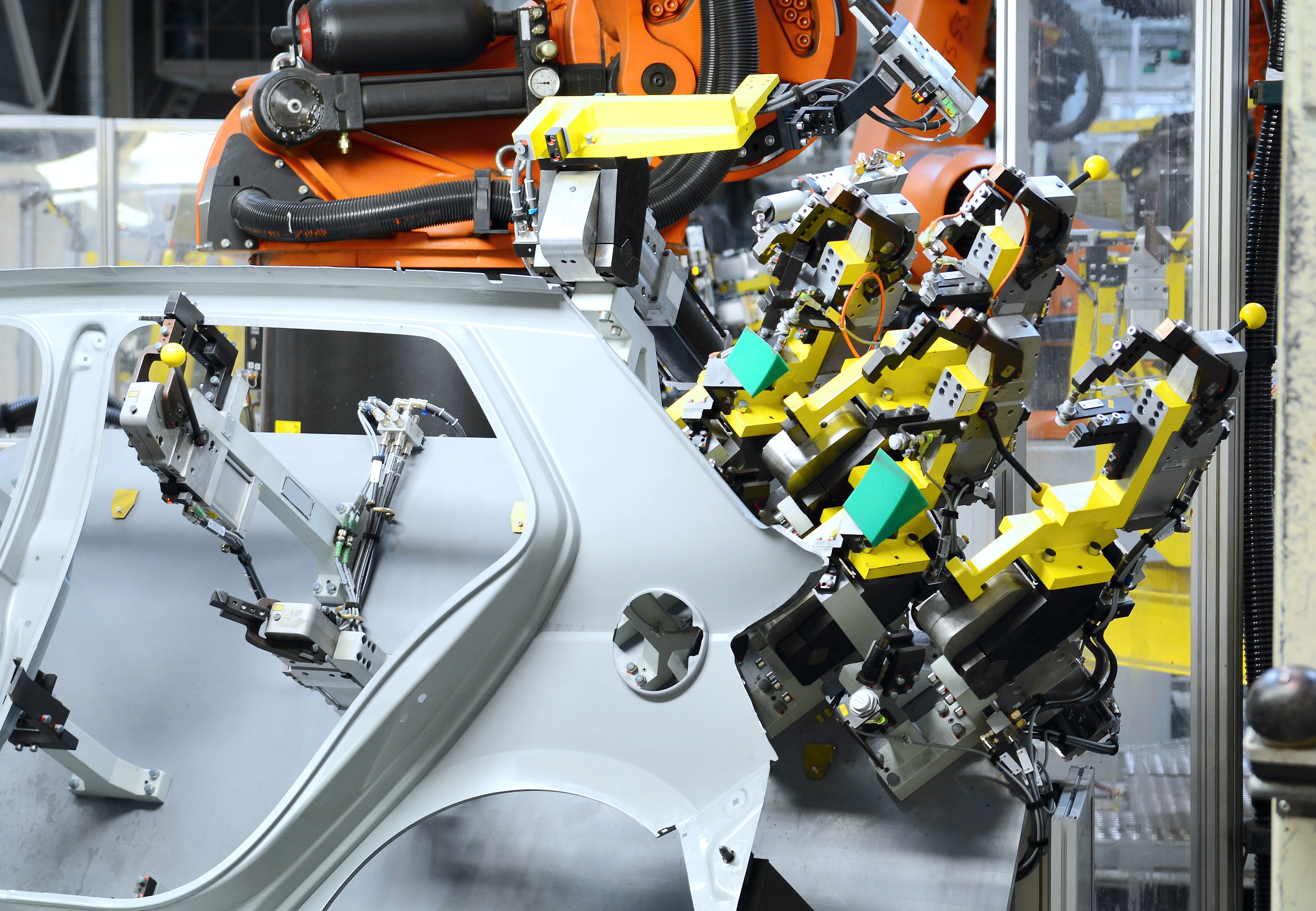

Simulation in mechanical engineering plays a crucial role as it enables complex systems to be analyzed, tested and optimized virtually. It is an indispensable tool for improving machine and process performance, reducing production times and avoiding costly errors. It enables potential problems and errors to be identified and fixed early before expensive physical prototypes have to be built. As a result, costs for materials, production and rework can be saved. Virtual tests and experiments can also be used to validate new ideas quickly and inexpensively.

Both engineering and simulation are essential tools to meet the challenges of modern mechanical engineering and remain competitive.

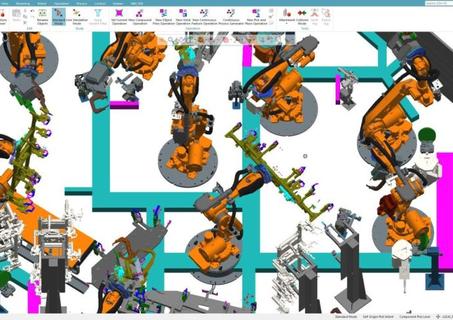

Our engineering team has many years of experience in design, simulation and offline programming (OLP). At the turn of the millennium still with Tecnomatix RobCAD©, for more than 10 years with Siemens Tecnomatix Process Simulate/Process-Designer©. With our state-of-the-art workstations, our own licenses and resources, we are able to independently and successfully handle projects with over 230 robots.

Our tasks include:

- Layout Planning

- Path Planning, Range Tests

- Resource Selection and Placement

- Reachability studies

- Accessibility tests

- Resource modeling (static and dynamic)

- Kinematization of resources

- Sequence / Cycle time optimization

- Simulation of complex manufacturing processes

- Offline programming and download of robot programs in product-specific customization

- a.m.m.