The ever shorter construction times of the systems require a high quality of the system software and the robot programs at an early stage of the project. With virtual commissioning, it is possible to react to this requirement from industry in advance, since the VIBN corresponds to real commissioning with a virtualized machine or system

Virtual commissioning in industry offers a multitude of advantages that help companies to work more efficiently and cost-effectively. Below are some of the key benefits of this technology.

Cost savings: Virtual commissioning enables companies to optimize their production processes without creating expensive physical prototypes or test facilities. By simulating production processes, potential problems can be identified and eliminated at an early stage, which leads to significant cost savings.

Time savings: Virtual commissioning enables companies to make their production processes faster and more efficient. The simulation makes it possible to test and optimize different scenarios before physical production begins. This eliminates errors and delays, resulting in reduced time to market.

Improved quality: Virtual commissioning enables companies to analyze and optimize their products and production processes more precisely. The simulation allows potential sources of error to be identified and eliminated before production begins. This improves the quality of the products and reduces rejects.

Flexibility: Virtual commissioning enables companies to make their production processes more flexible. Through the simulation, different scenarios can be tested and optimized in order to be able to react to changing market conditions or customer requirements. This enables companies to react more quickly to changes and remain competitive.

Education and training: Virtual commissioning also offers advantages in the area of education and training. Employees can be trained in a virtual environment to learn complex production processes or to operate new machines. This reduces training costs and improves employee efficiency.

Overall, virtual commissioning in industry offers a multitude of advantages that help companies to optimize their production processes, reduce costs and improve the quality of their products. By simulating production processes, companies can work more flexibly and efficiently and react more quickly to changes. Virtual commissioning is therefore an important technology to remain competitive and to meet market requirements.

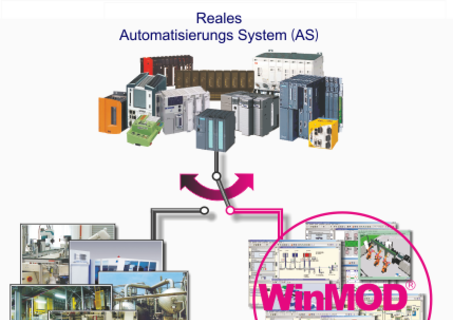

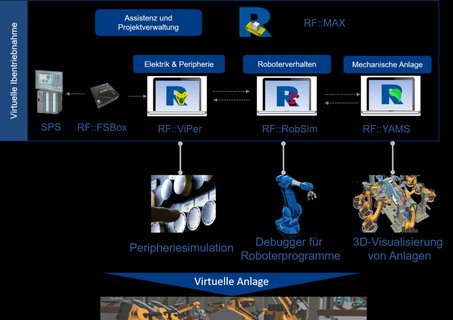

The software we use is WinMOD (Mewes & Partner) and RF:Suite (EKS InTec GmbH) and ISG-virtuos (ISG Industrial Control Technology GmbH)